18

2022

-

08

Brake Tricks You Should Know

A brake is a device with functions such as decelerating, stopping, or maintaining a stopped state of moving parts (or moving machinery). It is a mechanical part that stops or decelerates the moving parts in the machine, commonly known as the brake.

A brake is a device with functions such as decelerating, stopping, or maintaining a stopped state of moving parts (or moving machinery). It is a mechanical part that stops or decelerates the moving parts in the machine, commonly known as the brake.

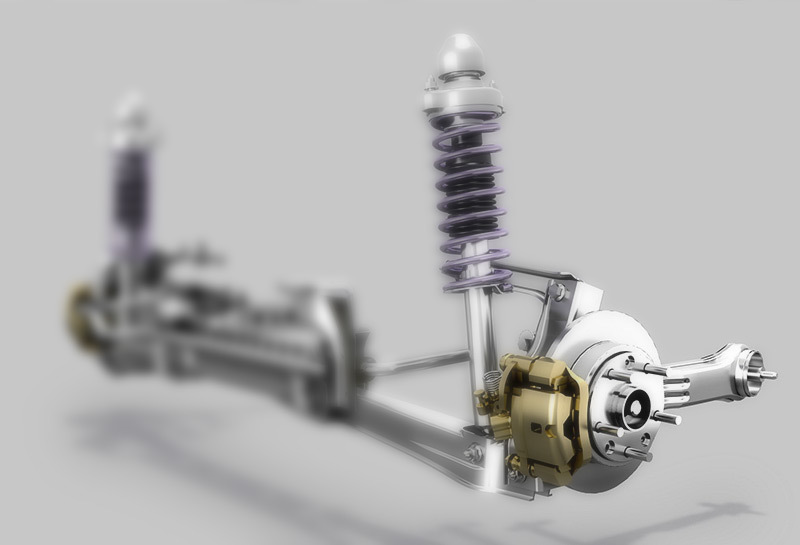

The brake is mainly composed of a frame, a braking part and a control device. Some brakes are also equipped with automatic adjustment devices for brake clearance. In order to reduce the braking torque and structure size, the brake is usually installed on the high-speed shaft of the equipment, but large equipment with high safety requirements (such as mine hoists, elevators, etc.) should be installed on the low-speed shaft close to the working part of the equipment superior. The brake on the fan, mounted on the rotating brake disc, is used for parking braking, working braking and emergency braking. In order to reduce the braking torque and structural size, the brake is usually installed on the high-speed shaft side of the gearbox. The brake is a hydraulically actuated disc brake, normally closed, with automatic brake clearance compensation.

The brake has the following two braking methods:

(1) Active type: pressurized braking, pressure relief open (SL3000)

(2) Passive: pressurized open, pressure relief brake (SL1500)

The belt brake has a large force on the axle and bearing, and the pressure between the belt and the wheel is uneven, so the wear is uneven and easy to break. However, the structure is simple and the size is compact, which can generate a large braking torque. application.

The block brake relies on the friction between the pad and the brake wheel to brake.

Internal expansion brake, this kind of brake has a compact structure and is widely used in various vehicles and machinery with limited structural size.

Drum brakes are an early type of brakes used in automobiles, and they are also more commonly used in trucks or passenger cars. Compared with disc brakes, drum brakes have the great advantage that they can generate huge braking force with less force, but their resistance to heat and water recession, self-adjustment of brake clearance, and stability of braking direction are relatively low. Difference.

Most vehicles now use disc brakes. When the brake pedal is depressed, the brake pads mounted on the inside and outside of the housing are pressed against the rotating brake disc by hydraulic pressure. Kinetic energy is converted into heat through friction and the car is braked. Disc brakes are superior to drum brakes in terms of performance, sensitivity and maintainability.

Keywords:

Related news